DTF Custom Transfers utilize a revolutionary printing method to create vibrant, detailed designs on fabric using heat press machines and specialized film. Optimal performance requires precise temperature and pressure settings tailored to material types, clean work area preparation, and accurate alignment. Mastering DTF techniques involves understanding fabric properties, proper preparation, even pressure application, and experimentation with timing and settings for exceptional results.

Discover the art of creating custom designs with DTF (Direct-To-Fabric) transfers using a heat press. This comprehensive guide breaks down the process into three key sections. First, we’ll explore the materials and fundamentals of DTF transfers. Next, learn how to optimize your heat press for precise results. Finally, master application techniques to ensure vibrant, long-lasting designs on a variety of fabrics. Elevate your custom transfer game with these essential tips.

- Understanding DTF Custom Transfers: Materials and Basics

- Setting Up Your Heat Press for Optimal Performance

- Mastering Transfer Application Techniques and Tips

Understanding DTF Custom Transfers: Materials and Basics

DTF Custom Transfers (Direct to Fabric) are a cutting-edge method revolutionizing the world of custom printing. This technique involves transferring intricate designs directly onto fabric using heat and pressure, offering unparalleled detail and vibrancy. The process starts with DTF transfer film, a special material designed to accept ink and seamlessly adhere to textiles. This film is precisely cut to match the desired design, ensuring crisp lines and precise color reproduction.

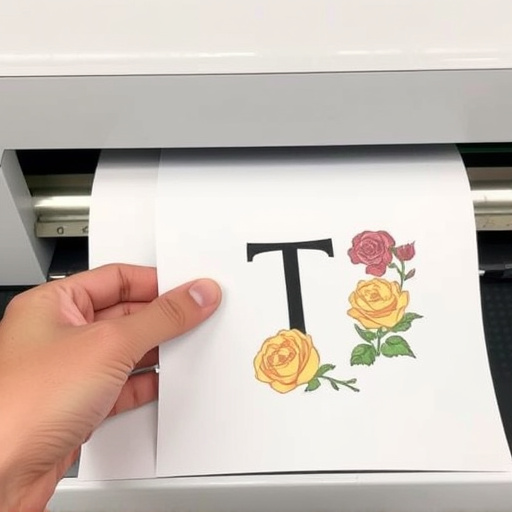

When preparing for DTF printing for t-shirts or other fabrics, it’s crucial to understand the materials. The film is typically made from a thin, flexible polymer that allows for smooth transfer of ink. Heat press machines play a pivotal role in this process, applying controlled heat and pressure to fuse the design onto the fabric permanently. By mastering these elements—from selecting suitable DTF transfer film to optimizing heat press settings—creatives can achieve exceptional results, transforming blank canvases into eye-catching garments or accessories.

Setting Up Your Heat Press for Optimal Performance

To achieve optimal performance with DTF Custom Transfers, proper heat press setup is paramount. Begin by ensuring your heat press machine is calibrated accurately according to the manufacturer’s guidelines. This involves setting the temperature and pressure settings suitable for the specific DTF prints you intend to apply. Different materials, like cotton, polyester, or blends, require precise parameters to achieve crisp, long-lasting transfers.

Next, prepare your work area by laying out all necessary tools and materials in an organized fashion. Have your heat press mat ready, ensuring it’s clean and in good condition. Position the press plate accurately, aligning it correctly with the transfer design you’re using. For clothing brands looking to add logos DFT for their merchandise, this meticulous setup process guarantees that each print is consistently of high quality, allowing you to achieve professional results with your DTF prints.

Mastering Transfer Application Techniques and Tips

Mastering the art of applying custom DTF (Direct to Fabric) transfers is a crucial step in achieving high-quality results with your heat press. The key lies in understanding the unique properties of DTF for Apparel and practicing various application techniques. Start by preparing your fabric; ensure it’s clean, dry, and free from any oils or stains that could hinder adhesion. Preheating the garment is essential, so set your heat press to the appropriate temperature as recommended by the DTF heat transfer paper manufacturer.

When applying the transfer, use a smooth, even pressure and make sure the entire design is in contact with the fabric. Avoid over-pressing, which can cause the paper to adhere too tightly, making removal difficult. For best results, work in sections, especially for larger designs. Experiment with different application times and pressure settings to achieve a crisp, vibrant transfer. Practice will refine your skills, ensuring you consistently deliver exceptional custom DTF transfers.

DTF Custom Transfers offer a dynamic way to create unique, high-quality designs. By understanding the materials, setting your heat press optimally, and mastering application techniques, you can achieve professional results in no time. With these steps, you’re well-equipped to explore the world of DTF printing, bringing your creative visions to life with precision and efficiency.