DTF (Direct to Fabric) custom transfers revolutionize apparel design by offering flexible, high-quality printing on various fabrics using specialized inks and materials. Effective graphic design principles, focusing on color theory, composition, and print quality, ensure visually striking and durable transfers suitable for fashion, branding, or personal expression. Proper printing techniques and heat pressing secure long-lasting, vibrant designs on diverse fabric types, making DTF transfers a popular choice for bulk shirt production.

Designing graphics for effective DTF (Direct to Garment) custom transfers requires a thoughtful balance of aesthetics and practicality. This article guides you through the process, starting with an in-depth look at DTF transfer materials and techniques. We explore powerful visual elements like color, contrast, and composition to create captivating designs. Additionally, we delve into optimizing design choices for superior print quality and durability, ensuring your DTF custom transfers leave a lasting impression on both fabric and viewers alike.

- Understanding DTF Transfers: Materials and Techniques

- Visual Elements for Impact: Color, Contrast, and Composition

- Optimizing Design for Print Quality and Durability

Understanding DTF Transfers: Materials and Techniques

Understanding DTF Transfers: Materials and Techniques

DTF (Direct to Fabric) custom transfers have revolutionized the way we design and print on apparel, offering a versatile and efficient method for creating custom t shirts and other textiles. The process involves using specialized DTF transfer film or sheets that are applied directly onto fabric, enabling long-lasting, high-quality prints. These materials come in various types, each suited for different fabrics and printing techniques, such as vinyl, polyurethanes, or water-based inks.

The technique begins with designing the artwork using graphic design software, which is then printed onto the chosen DTF transfer film or sheet. Once prepared, the transfer is applied to the target fabric using heat and pressure. This method allows for intricate designs, vibrant colors, and a range of textures, making it suitable for both simple and complex custom t shirt designs. By understanding the materials and techniques involved in DTF transfers, designers can effectively bring their creative visions to life on various fabric mediums.

Visual Elements for Impact: Color, Contrast, and Composition

In designing graphics for effective DTF custom transfers, visual elements play a pivotal role in capturing attention and conveying messages. Color is a powerful tool that can evoke emotions, enhance visibility, and differentiate designs. When creating artwork for DTF (Direct to Fabric) transfers, understanding color theory is essential. Complementary colors or those located opposite each other on the color wheel, like blue and orange, create vibrant contrast when placed together. This high-contrast palette can make your graphics stand out, especially when printed on light or dark fabric backgrounds.

Composition refers to how elements are arranged within a design, guiding the viewer’s eye through the artwork. A balanced composition ensures that no part of the graphic dominates, allowing key messages or designs to capture focus. For DTF custom graphic tees, aligning text with eye-catching graphics or strategically placing images can create an appealing layout. The bulk DTF shirt production process benefits from these design principles, as they ensure that each transfer is not only visually striking but also effectively communicates the intended message, whether for fashion statements, branding, or personal expression, making cold peel DTF transfers a versatile and popular choice.

Optimizing Design for Print Quality and Durability

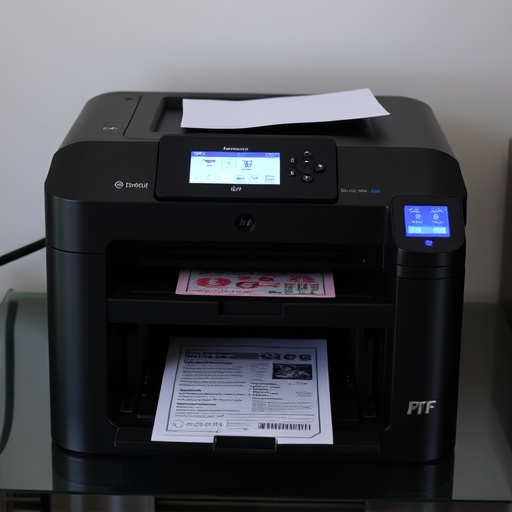

When designing graphics for DTF (Direct to Fabric) custom transfers, prioritizing print quality and durability is paramount. The best dtf printer relies on high-resolution designs with clean lines and sharp details to ensure the final transfer accurately replicates the original artwork. Using vector graphics or optimizing raster images at a suitable resolution ensures smooth reproduction without pixelation or blurriness, especially for intricate patterns and fine lines.

Durability is another critical aspect, particularly when applying DTF transfers to items like t-shirts that undergo frequent washing. Consider using vibrant but light-fast inks and ensuring the design is set correctly during printing. Proper heat pressing at the right temperature and pressure also plays a significant role in securing the transfer’s longevity, preserving the vibrancy of colors and the overall quality of the print on various fabric types.

Designing graphics for effective DTF custom transfers requires a blend of understanding transfer materials, leveraging visual impact through color and contrast, and optimizing designs for superior print quality and durability. By combining these key elements, designers can create captivating DTF transfers that enhance various products with vibrant, long-lasting aesthetics.